PRODUCTS

Choose from Our Range of Products

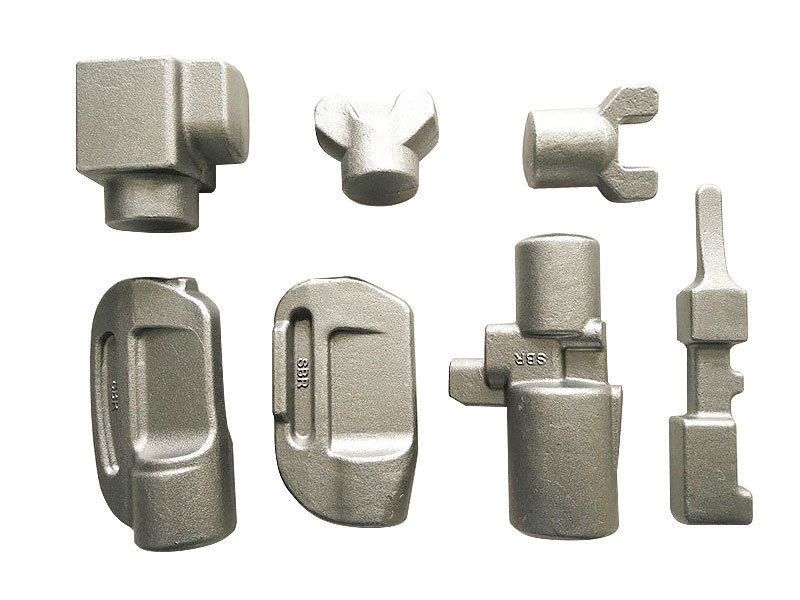

Main Products: Our company mainly supplies the forklift hook, automobile fttings, construction machinery components, rail parts and chemical reactor tank spare parts.

ABOUT US

Hongxin Precision Forging

One of The Leading Forging Manufacturers in China

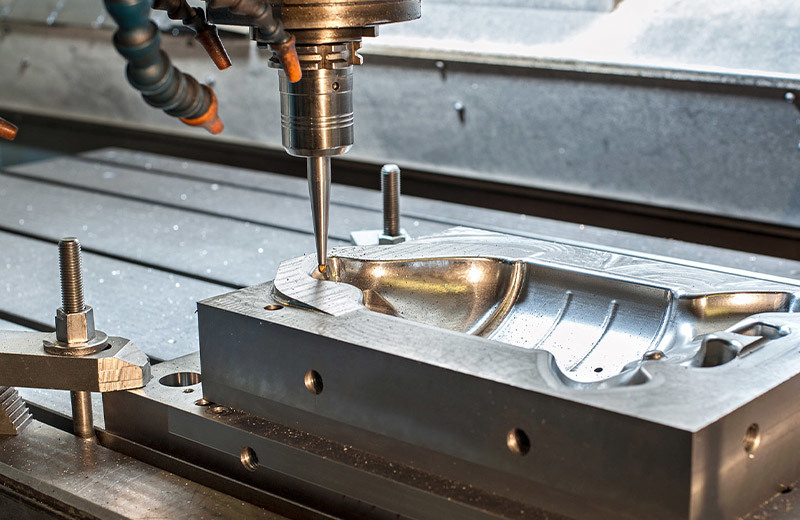

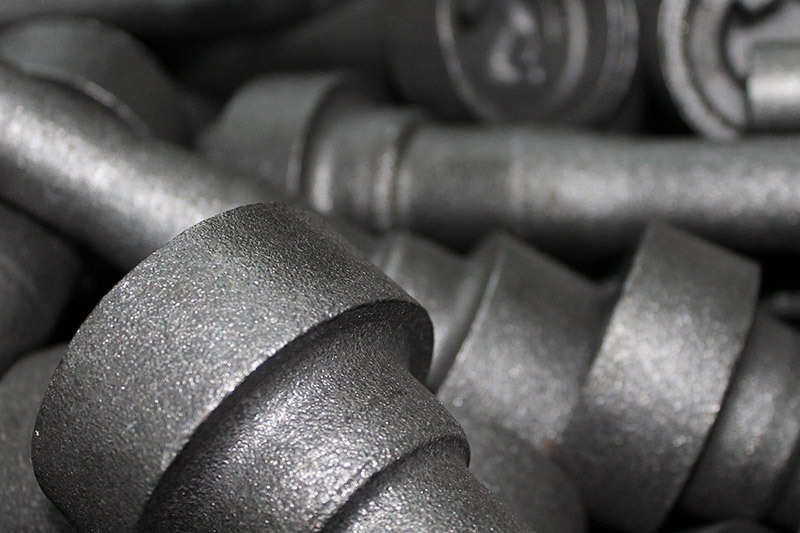

The main forging equipment includes: the remote controlled hydraulic forging hammer, the friction press, the medium frequency furnace , 100T punch and so on; CNC miling machine, linear cutting machine, EDM machine etc. different kinds of tooling machining equipment, also equipped with ordinary machining equipment, which include vertical machining centre etc. Our company mainly supplies the forklift hook, automobile fttings, construction machinery components, rail parts and chemical reactor tank spare parts.

Experience of forging productions

Production and testing equipment

Exporting countries and regions

CUSTOMIZED

OEM/ODM Service

With a strong technical force, advanced production process, strictly quality control and short development lead time, in time delivery to make sure that only the best parts reach our clients.

The professional workers and advanced facility can make the quality more refined with high productivity,the Bulk production can save single piece cost.

Hongxin's machining workshop can supply CNC machining processes including turning, milling, planing, boring,reaming and so on.

For regular parts,we always have stock and for customized parts,from make mold to bulk production,normally 30-40 days.

APPLICATION

Industries Served With forging Parts

As a forging parts manufacturer, we produce various components. And the industries we are involved in include kinds of fork, industrial equipment, construction fields, automotive fabrication, railway engineering, chemical industry, etc.

Fork

Railway

Machinery

Industrial

Automobile

Mining

BLOG

News & Media

Jun 14,2024

What are the application advantages of OEM forgings?

Jun 14,2024

How to measure the quality of OEM forgings?

Jun 14,2024

Defects often caused by improper forging process

Jun 14,2024

Common forging methods and their advantages and disadvantages

GET IN TOUCH

Didn't find the product you need, We support customization!

We has established our quality management policy in strict accordance with the ISO 9001 standard. Hongxin dedicates itself to creating value for customers by supplying quality forging products and developing long-term partnerships.