Jun 14,2024

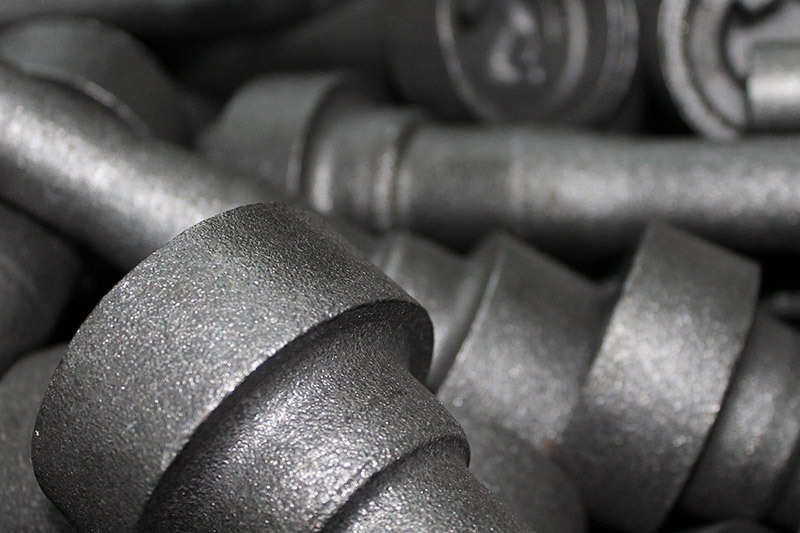

What are the application advantages of OEM forgings?

Higher quality than castings. The mechanical properties of OEM forgings are better than those of castings and they can withstand large impact forces and other heavy loads.

Jun 14,2024

What is the scope of OEM forgings?

In forging, pressure can be applied to metal blanks to plastically deform OEM forgings and change their mechanical properties. The looseness of the metal can be eliminated by forging.

Jun 14,2024

Defects often caused by improper forging process

Large grains are usually caused by high initial forging temperature and insufficient deformation degree, or high final forging temperature or deformation degree falling into the critical deformation zone.

Jun 14,2024

Common forging methods and their advantages and disadvantages

Free forging refers to the machining method of forgings that uses simple universal tools or applies external forces directly between the upper and lower anvils of forging equipment to deform the billet and obtain the required geometric shape and internal quality.

Jun 14,2024

Four inspection methods for forging of construction machinery

Engineering machinery forgings need to meet certain requirements according to the production line of the product, so that they can only be put into use after meeting the standards. Now let me tell you how to meet the standards.

Jun 14,2024

What should we pay attention to when forging?

When considering the forging temperature, the temperature drop during the contact process between the blank and the mold should be taken into account, and the mold should be preheated.

Jun 14,2024

How to measure the quality of OEM forgings?

The main forging equipment includes: the remote controlled hydraulic forging hammer, the friction press, the medium frequency furnace , 100T punch and so on;

Jun 14,2024

Common machining methods and processing ranges

Turning: Inner and outer cylindrical surfaces, conical surfaces, end faces, grooves, threads, etc. Milling: Plane, groove, gear, spline, curved surface, etc.

Jun 14,2024

The classification of Forging processes

Free forging generally refers to the method of using simple tools on a forging hammer or hydraulic press to hammer the metal ingots or blocks into the required shape and size.

Jun 14,2024

The production process of forging

The quality of forgings is higher than that of castings, and they can withstand greater impact forces. Their mechanical properties, such as plasticity, toughness, and others, are also higher than castings and even some rolled products.

Contact Us

E-mail :

hongxinjingduan@163.com

Phone/WhatsApp:

+86-13932867896, +86-15603187896

Address:

Longhua Town, Jing county, Hebei Province, China